1. Tshekatsheko ya popego

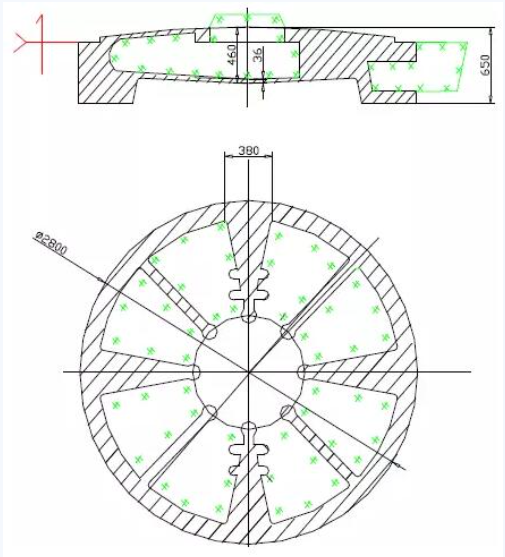

(1) Senobelefo ya serurubelee na le sebopeho se sediko sa sebopeho sa kuku, lesoba le ka hare le hokahantswe le ho tshehetswa ke dikgopo tse 8 tse matlafatsang, lesoba le hodimo la Φ620 le buisana le lesoba le ka hare, mme karolo e setseng yabelefoe tswetswe, konokono ya motlhaba e thata go e baakanya e bile go bonolo go e senyega. Bobedi go ntsha gase le go phepafatsa leroba le le ka fa gare go tlisa mathata a magolo, jaaka go bontshitswe mo Setshwantshong 1.

Bokima jwa lebota jwa di-casting bo farologana thata, bokima jo bo kwa godimo jwa lebota bo fitlha go 380mm, mme bokima jo bo kwa tlase jwa lebota ke 36mm fela. Fa go latlhela go tiisitswe, pharologano ya themperetšha e kgolo, mme go ngotlega go go sa lekalekaneng go ka tlhagisa bonolo dikhuti tsa go ngotlega le diphoso tsa porosity ya go ngotlega, tse di tla bakang go elela ga metsi mo tekong ya haeteroliki.

2. Moakanyetso wa thulaganyo:

(1) Boalo jwa go kgaoganya bo bontshitswe mo Setshwantshong 1. Beya ntlha e e nang le dikhuti mo lebokosong le le kwa godimo, dira konokono yotlhe ya motlhaba mo lesobeng le le fa gare, mme o lelefatse tlhogo ya konokono ka tshwanelo go tlhofofatsa go bofa ga konokono ya motlhaba le motsamao wa konokono ya motlhaba fa lebokoso le retololwa. Tsepameng, bolelele ba cantilever konokono hlooho ya tse peli tse foufetseng mekoting ka lehlakoreng e telele ho feta bolelele ba lesoba, e le hore setsi sa matla a khoheli eohle lehlabathe konokono e biased ho lehlakoreng la hlooho konokono ho netefatsa hore lehlabathe konokono e tsitsitse le tsitsitseng.

Go amogelwa thulaganyo ya go tshela e e tswetsweng go sekae, ∑F mo teng: ∑F e e rapaletseng: ∑F e e tlhamaletseng=1:1.5:1.3, sprue e dirisa tšhupu ya seramiki e e nang le molagare wa ka fa teng wa Φ120, mme dikarolo tse pedi tsa 200×100yfractor×40mm di bewa mo diteneng tshipi go tswa ka tlhamalalo Bakeng sa tshusumetso lehlabathe mouta, e 150 × 150 × 40 bubble ceramic filthara e hlomamisa ka tlase ho matha, 'me 12 ceramic dipeipi le bophara ba ka hare ba Φ30 di sebediswa bakeng sa ka hare matha ho hokahanya ka ho lekanang le tlase ya filthara potom ka bolleut metsi a colleu t sekema sa go tshela, jaaka go bontshitswe mo Setshwantshong 2 Botlhokwa

(3) Beha 14 ∮20 lesoba moea mekoting ka holimo mouta, beha Φ200 lehlabathe konokono vent lesoba bohareng ba hlooho konokono, beha batang tšepe ka likarolo tse teteaneng le tse khōlō ho netefatsa hore ho leka-lekaneng solidification ea ho lahla, 'me sebelisa graphitization katoloso ya tshebetso user ho The graphitization katoloso ya tshebetso ke ho. Bogolo jwa lebokoso la motlhaba ke 3600×3600×1000/600mm, mme le kopantswe ka poleiti ya tshipi e e bokima jwa 25mm go netefatsa maatla a a lekaneng le go gagamala, jaaka go bontshitswe mo Setshwantshong 3.

3. Taolo ya thulaganyo

(1) Go dira sekao: Pele ga go dira sekao, dirisa sampole e e tlwaelegileng ya Φ50×50mm go leka maatla a kgatelelo ya motlhaba wa resin ≥ 3.5MPa, mme o gagamatse tshipi e e tsididi le motabogi go netefatsa gore mouta wa motlhaba o na le maatla a a lekaneng go fokotsa graphite e e tlhagisiwang fa motlhaba wa motlhaba o o nyerologang le Chemiron e e nyerologang go tswa mo go thuleng karolo ya motabogi ka nako e telele go baka go tlhatswiwa ga motlhaba.

Go dira konokono: Motheo wa motlhaba o kgaogantswe ka dikarolo di le 8 tse di lekanang ke dikgopo di le 8 tse di nonotshang, tse di golagantsweng ka leroba le le fa gare. Ga go na dikarolo tse dingwe tsa tshegetso le tsa go ntsha mosi kwa ntle ga tlhogo ya konokono e e fa gare. Fa konokono ya motlhaba e sa kgone go baakanngwa le Exhaust, go suta ga konokono ya motlhaba le dikhutsi tsa mowa di tla tlhagelela morago ga go tshela. Ka gonne karolo yotlhe ya konokono ya motlhaba e le kgolo, e kgaogantswe ka dikarolo di le robedi. E tshwanetse go nna le maatla a a lekaneng le go gagamala go netefatsa gore konokono ya motlhaba ga e kitla e senyega morago ga go gololwa ga mouta, mme ga e kitla e senyega morago ga go tshelwa. Deformation etsahala, e le hore ho netefatsa junifomo leboteng botenya ba lahla. Ka lebaka le, re ne ra dira lerapo le le kgethegileng la konokono ka tsela e e kgethegileng, mme ra le bofa mo lerapong la konokono ka thapo ya go tsenya mowa go goga gase ya go tswa mo tlhogong ya konokono go netefatsa gore mouta wa motlhaba o kopane fa re dira konokono. Jaaka go bontshitswe mo Setshwantshong 4.

(4) Lebokoso la go tswala: Fa re akanya ka gore go thata go phepafatsa motlhaba mo lerobeng le le kafa teng la belofo ya serurubele, konokono yotlhe ya motlhaba e pentilwe ka dikarolo tse pedi tsa pente, karolo ya ntlha e borashewa ka pente ya zirconium e e theilweng mo bojalweng (Baume degree 45-55), mme karolo ya ntlha e pentilwe ka burne. Morago ga go omisa, penta llaga ya bobedi ka pente ya magnesium e e nang le bojalwa (Baume degree 35-45) go thibela gore se se latlhetsweng se se ka sa kgomarela motlhaba le go tlhotlhorega, se se ka se kgoneng go phepafadiwa. Karolo ya tlhogo ya konokono e fanyegilwe mo peiping ya tshipi ya Φ200 ya sebopego se segolo sa lerapo la konokono ka dikurufu tse tharo tsa M25, e tlhomamisitswe le go notlelwa ka lebokoso la motlhaba la mouta le le nang le dikhurumelo tsa sekurufu mme ya tlholwa gore a botenya jwa lebota jwa karolo nngwe le nngwe bo tshwana.

4. Thulaganyo ya go nyerologa le go tshela

(1) Dirisa Benxi tlaase-P, S, Ti boleng bo phahameng Q14 / 16 # kolobe tšepe, 'me e eketsa ka tekanyo ea 40% ~ 60%; dielemente tsa motlhala tse di jaaka P, S, Ti, Cr, Pb, jj di laolwa thata mo tshiping e e latlhilweng, mme ga go letlelelwe rusi le oli , selekanyo sa tlaleletso ke 25%~40%; tšhatšhe e e busitsweng e tshwanetse go phepafadiwa ka go thunya ka go thunya pele ga tiriso go netefatsa bophepa jwa tšhatšhe.

(2) Taolo ya karolo e kgolo morago ga onto: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (masalela): 0.035% ~0.05%, ka fa tlase ga tekanyetso ya (masalela) e tshwanetse go tsewa ka fa go ka kgonegang ka teng.

(3) Kalafo ya go enta ya go dira gore e nne kgolokwe: go dirisiwa dikgolokwe tse di nang le magnesium e e kwa tlase le tse di nang le lefatshe le le sa tlwaelegang, mme selekanyo sa tlaleletso ke 1.0% ~ 1.2%. Mokgwa o o tlwaelegileng wa go tlhatswa wa kalafi ya go dira gore go nne le kgolokwe, 0.15% ya go enta ga nako e le nngwe e khurumeditswe mo nodulizer kwa tlase ga sephuthelwana, mme go dira gore go nne le kgolokwe go a wediwa. Slag e bo e tsenngwa mo konterakeng e e kwa tlase go enta ga bobedi ga 0.35%, mme go enta ka kelelo ya 0.15% go dirwa ka nako ya go tshela.

(5) Tlase mocheso ka potlako tšela tshebetso e amohetsweng, tšela mocheso ke 1320 ° C ~ 1340 ° C, 'me nako tšela ke 70 ~ 80s. Tshipi e e nyerolotsweng ga e ka ke ya kgaosediwa ka nako ya go tshela, mme kopi ya sprue e nna e tletse go thibela gase le di-inclusions go nna le seabe mo sebopegong ka motabogi. leroba.

5. Dipholo tsa teko ya go latlhela

(1) Leka maatla a go gagamala a boloko ya teko e e latlhetsweng: 485MPa, boleele: 15%, bothata jwa Brinell HB187.

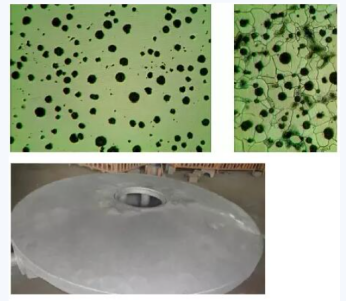

(2) Seelo sa go nna kgolokwe ke 95%, bogolo jwa kerafaete ke mophato wa 6, mme pearlite ke 35%. Popego ya metalokerafi e bontshiwa mo Setshwantshong 5.

(3) Ga go na diphoso tse di ka kwalwang tse di neng tsa fitlhelwa mo go lemogeng diphoso tsa bobedi tsa UT le MT tsa dikarolo tsa botlhokwa.

(4) Ponagalo e sephaphathi e bile e borethe (bona Setshwantsho 6), ntle le diphoso tsa go latlhela tse di jaaka di-inclusion tsa motlhaba, di-slag di-shut, di-shut tse di tsididi, jj., botelele jwa lebota bo a tshwana, mme ditekanyo di fitlhelela ditlhokego tsa ditshwantsho.

(6) Teko ya kgatelelo ya haeteroliki ya 20kg/cm2 morago ga go dira ga e a bontsha go dutla gope

6. Bokhutlo

Ho ea ka dipharologantsho tsa sebopeho sa sena serurubele belofo, bothata ba sa tsitsang le bonolo deformation ya kgolo lehlabathe konokono ka bohareng le thata lehlabathe ho hloekisa e rarolloa ka ho hatisa ka moralo wa tshebetso moralo, tlhahiso le ho lokisa ya lehlabathe konokono le tshebediso ya zirconium-thehiloeng coatings. Go bewa ga dikhutsi tsa go ntsha mowa go tila kgonagalo ya dipore mo di-casting. Ho tloha ontong qoso taolo le runner tsamaiso, bubble ceramic filthara skrine le ceramic ingate thekenoloji di sebediswa ho netefatsa bohlweki ba tšepe qhibilihile. Morago ga dikalafi tse dintsi tsa go enta, popego ya metallographic ya di-casting le tse di farologaneng Tshebetso e e akaretsang e fitlheletse ditlhokego tse di tlwaelegileng tsa bareki .

Go tswa moTianjin Tanggu Belofo ya go tswalela metsi Co. Belofo ya serurubele, belefo ya heke, Sefepi sa Y, belofo ya go tlhola dipoleiti tse pedi tsa wafergo dira.

Nako ya go romelwa: Moranang-29-2023