ANSI/DIN/API/BS4504 Tshipi e e Borethe/WCB/CF8M Mmele wa PTFE/NBR/EPDM Setulo le Moakanyetso o o Tsepameng wa Wafer/Belefo ya Serurubele e e nang le Flange

“Boammaaruri, Boitshimololedi, Bogale, le Bokgoni” e ka nna kgopolo e e sa kgaotseng ya mokgatlho wa rona go ya kwa pakeng e telele go aga mmogo le bareki go dirisana mmogo le go solegela botlhe molemo mo Setlhopheng sa Boleng jo bo kwa Godimo 150 Pn10 Pn16 Ci Di .Belofo ya Serurubele ya Mofuta wa WaferRubber Seat Lined, Re amohela baeti bohle ka botshepehi ho hlophisa dikamano tsa khamphani le rona ka motheo wa dikarolo tse ntle tse kopanetsweng. O tshwanetse go ikgolaganya le rona gone jaanong. O ka bona karabo ya rona e e nang le bokgoni mo teng ga diura di le mmalwa tsa 8.

“Boammaaruri, Boitshimololedi, Bogagapa, le Bokgoni” e ka nna kgopolo e e sa kgaotseng ya mokgatlho wa rona go ya go nako e telele go aga mmogo le bareki go dirisana mmogo le go solegela botlhe molemo ka 2019.belofo ya serurubele; belefo ya serurubele ya mofuta wa wafer, Ka maikaelelo a “go tlhoka bokoa”. Go tlhokomela tikologo, le dipoelo tsa loago, tlhokomela modiri boikarabelo jwa loago jaaka tiro ya gagwe. Re amogela ditsala go tswa lefatsheng ka bophara go re etela le go re kaela gore re kgone go fitlhelela mokgele wa phenyo mmogo.

Tlhaloso:

Tlhatlhamano ya YDBelefo ya serurubele e e nang le rabara ya wafer's flange kgokelo ke bokahohleng tekanyetso, 'me lintho tse bonahalang tsa setshwaro ke aluminiamo;E ka sebediswa e le sesebediswa ho khaola-off kapa laola phallo ka liphaephe tse sa tšoaneng mahareng. Ka ho khetha thepa e fapaneng ya diseke ee le tiiso setulo, hammoho le pinless kgokelo pakeng tsa diseke ee le kutu,belofo ka sebediswa ho maemo a mpe le ho feta, tse kang desulphurization lefeela, leoatle metsi desalinization.

Belofo e na le moakanyetso o o kopaneng le o o botlhofo, o o dirang gore go nne bonolo thata go e tsenya le go e dirisa. Thulaganyo ya yone ya mofuta wa wafer e letla gore go tsenngwe ka bonako le bonolo fa gare ga di-flanges, go dira gore e nne e e siametseng sebaka se se pitlaganeng le ditiriso tse di sa tlhokomeleng bokete. Ka lebaka la ditlhoko tse tlase tsa torque, basebedisi ba ka fetola boemo ba belofo habonolo ho laola phallo ka nepo ntle le ho hatella disebediswa.

The ntlhakgolo ka sehloohong sa rona wafer serurubele di-valve ke bokgoni ba bona babatsehang phallo taolo. Eona e ikhethang diseke ee moralo bōpa laminar phallo, fokotsa kgatelelo ya lerotholi le maximizing tshebetso bokgoni. Seno ga se tokafatse fela go dira ga tsamaiso ya gago mme gape se fokotsa tiriso ya maatla, mme seno se felela ka gore o boloke ditshenyegelo tse dintsi mo tirong ya gago.

Pabalesego ke botlhokwa thata mo tikologong epe ya madirelo mme dibelofo tsa rona tsa serurubele sa wafer di ka fitlhelela ditlhoko tsa gago. E na le mokgwa wa go notlela wa pabalesego o o thibelang go dira ga belofo ka phoso kgotsa ka tsela e e sa letlelelweng, go netefatsa gore thulaganyo ya gago e tsamaya sentle ntle le go kgoreletsega gope. Ho feta moo, dithoto tsa yona tsa ho tiisa tse thata di fokotsa ho dutla, di eketsa botshepehi ba tsamaiso ka kakaretso le ho fokotsa kotsi ya ho se sebetse kapa kgotlelo ya sehlahiswa.

Go kgona go dira dilo tse dintsi ke selo se sengwe se se tlhomologileng sa dibelofo tsa rona tsa serurubele sa wafer. E loketse mefuta e fapaneng ya dikopo tse kenyeletsang kalafo ya metsi, dithulaganyo tsa HVAC, tshebetso ya dikhemikhale, oli le khase, le tse ling, di-valve di fana ka ditharollo tse tshepahalang, tse sebetsang hantle tsa taolo bakeng sa mefuta e fapaneng ya indasteri.

Ka bokhutshwane, di-valve tsa rona tsa serurubele sa wafer di fana ka ditharollo tse tshepahalang, tse sebetsang hantle le tse somarelang ditshenyehelo tsa taolo ya phallo bakeng sa dikopo tse fapaneng. Ka kaho ya yona e tsoarellang, ho kengwa ha bonolo, bokgoni bo phahameng ba ho laola phallo le dikarolo tse matla tsa polokeho, belofo ena ntle le pelaelo e tla feta ditebello tsa hao mme e bapala karolo ya motheo ho ntlafatsa bokgoni ba ditshebetso tsa hao. Itemogele tiragatso e e senang selekanyo ya dibelofo tsa rona tsa serurubele sa wafer mme o ise dithulaganyo tsa gago tsa madirelo kwa bogodimong jo bosha.

Ponagalo:

1. Nnye ka bogolo & lesedi ka boima le bonolo tlhokomelo. E ka tlhongwa gongwe le gongwe kwa go tlhokegang teng.

2. Popego e e bonolo, e e kopaneng, e e dirang ka bonako ka didikirii di le 90

3. Disc na tse peli-tsela behang, phethahetseng tiiso, ntle ho dutla tlas'a teko kgatello.

4. Sebopego sa kelelo se se nang le tshekamelo ya mola o o tlhamaletseng. Tshebetso e babatsehang ya molawana.

5. Mefuta e e farologaneng ya didirisiwa, tse di dirisiwang mo metsweding e e farologaneng ya dikgang.

6. Matla a hlatsoa le borashe hanyetsa, 'me e ka lumellane ho boemo bo bobe ba ho sebetsa.

7. Setsi poleiti sebopeho, torque nyenyane ya bulehileng le koala.

8. Botshelo jo boleele jwa tirelo. E eme teko ya dikete tse leshome tsa ho bula le ho koala ditshebetso.

9. E ka dirisiwa mo go kgaoleng le go laola bobegakgang.

Tiriso e e tlwaelegileng:

1. Ditiro tsa metsi le porojeke ya motswedi wa metsi

2. Tshireletso ya Tikologo

3. Dikago tsa Setšhaba

4. Motlakase le Ditirelo tsa Setšhaba

5. Intaseteri ya go aga

6. Petroliamo/ Khemikhale

7. Tshipi. Thuto ya tshipi

8. Intaseteri ya go dira dipampiri

9. Dijo/Dino jj

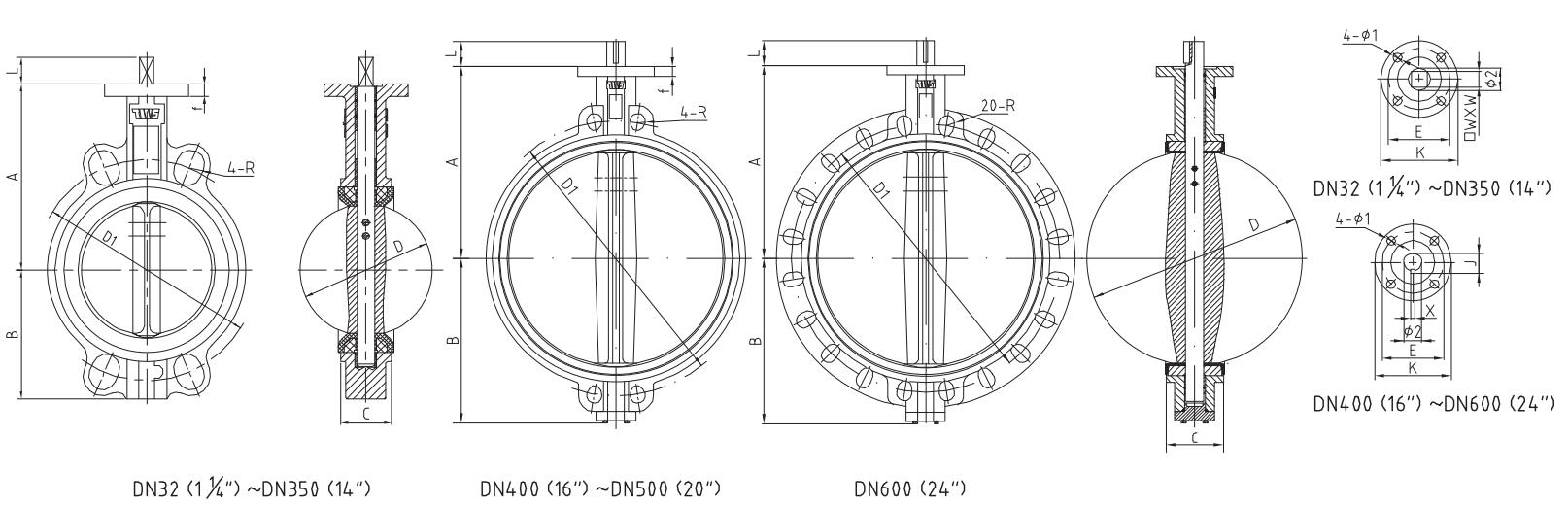

Bogolo:

| Tekanyo | A | B | C | D | L | D1 | D2 | Φ1 | ΦK | E | R1 (PN10) | R2 (PN16) | Φ2 | f | j | x | □w*w | Bokete (kg) | |

| mm | intšhe | ||||||||||||||||||

| 32 | 11/4 | 125 | 73 | 33 | 36 | 28 | 100 | 100 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.6 |

| 40 | 1.5 | 125 | 73 | 33 | 43 | 28 | 110 | 110 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.8 |

| 50 | 2 | 125 | 73 | 43 | 53 | 28 | 125 | 125 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 2.3 |

| 65 | 2.5 | 136 | 82 | 46 | 64 | 28 | 145 | 145 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3 |

| 80 | 3 | 142 | 91 | 46 | 79 | 28 | 160 | 160 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3.7 |

| 100 | 4 | 163 | 107 | 52 | 104 | 28 | 180 | 180 | 10 | 90 | 70 | R9.5 | R9.5 | 15.8 | 12 | – | – | 11*11 | 5.2 |

| 125 | 5 | 176 | 127 | 56 | 123 | 28 | 210 | 210 | 10 | 90 | 70 | R9.5 | R9.5 | 18.9 | 12 | – | – | 14*14 | 6.8 |

| 150 | 6 | 197 | 143 | 56 | 155 | 28 | 240 | 240 | 10 | 90 | 70 | R11.5 | R11.5 | 18.9 | 12 | – | – | 14*14 | 8.2 |

| 200 | 8 | 230 | 170 | 60 | 202 | 38 | 295 | 295 | 12 | 125 | 102 | R11.5 | R11.5 | 22.1 | 15 | – | – | 17*17 | 14 |

| 250 | 10 | 260 | 204 | 68 | 250 | 38 | 350 | 355 | 12 | 125 | 102 | R11.5 | R14 | 28.5 | 15 | – | – | 22*22 | 23 |

| 300 | 12 | 292 | 240 | 78 | 302 | 38 | 400 | 410 | 12 | 125 | 102 | R11.5 | R14 | 31.6 | 20 | – | – | 22*22 | 32 |

| 350 | 14 | 336 | 267 | 78 | 333 | 45 | 460 | 470 | 14 | 150 | 125 | R11.5 | R14 | 31.6 | 20 | 34.6 | 8 | – | 43 |

| 400 | 16 | 368 | 325 | 102 | 390 | 51/60 | 515 | 525 | 18 | 175 | 140 | R14 | R15.5 | 33.2 | 22 | 36.2 | 10 | – | 57 |

| 450 | 18 | 400 | 356 | 114 | 441 | 51/60 | 565 | 585 | 18 | 175 | 140 | R14 | R14 | 38 | 22 | 41 | 10 | – | 78 |

| 500 | 20 | 438 | 395 | 127 | 492 | 57/75 | 620 | 650 | 18 | 175 | 140 | R14 | R14 | 41.1 | 22 | 44.1 | 10 | – | 105 |

| 600 | 24 | 562 | 475 | 154 | 593 | 70/75 | 725 | 770 | 22 | 210 | 165 | R15.5 | R15.5 | 50.6 | 22 | 54.6 | 16 | – | 192 |

“Boammaaruri, Boitshimololedi, Bogale, le Bokgoni” e ka nna kgopolo e e sa kgaotseng ya mokgatlho wa rona go ya go nako e telele go aga mmogo le bareki go dirisana mmogo le go solegela molemo mmogo go bona Boleng jo bo kwa Godimo jwa Setlhopha sa 150 Pn10 Pn16 Ci Di Wafer Type Wecome Butterfly Rubber Seat, rulaganya dikamano tsa khamphani le rona ka motheo wa dikarolo tse ntle tse kopanetsweng. O tshwanetse go ikgolaganya le rona gone jaanong. O ka bona karabo ya rona e e nang le bokgoni mo teng ga diura di le mmalwa tsa 8.

Boleng jo bo kwa GodimoBelofo ya Serurubele ya Mofuta wa Wafer, Ka maikaelelo a “go tlhoka bokoa”. Go tlhokomela tikologo, le dipoelo tsa loago, tlhokomela modiri boikarabelo jwa loago jaaka tiro ya gagwe. Re amogela ditsala go tswa lefatsheng ka bophara go re etela le go re kaela gore re kgone go fitlhelela mokgele wa phenyo mmogo.